A watch is an instrument used to tell time using small, mechanical parts. Watches are made in a factory setting, with watch parts manufactured in one place and watch assembly taking place elsewhere. Many watch components are made by machine, but the assembly process is almost always done by hand.

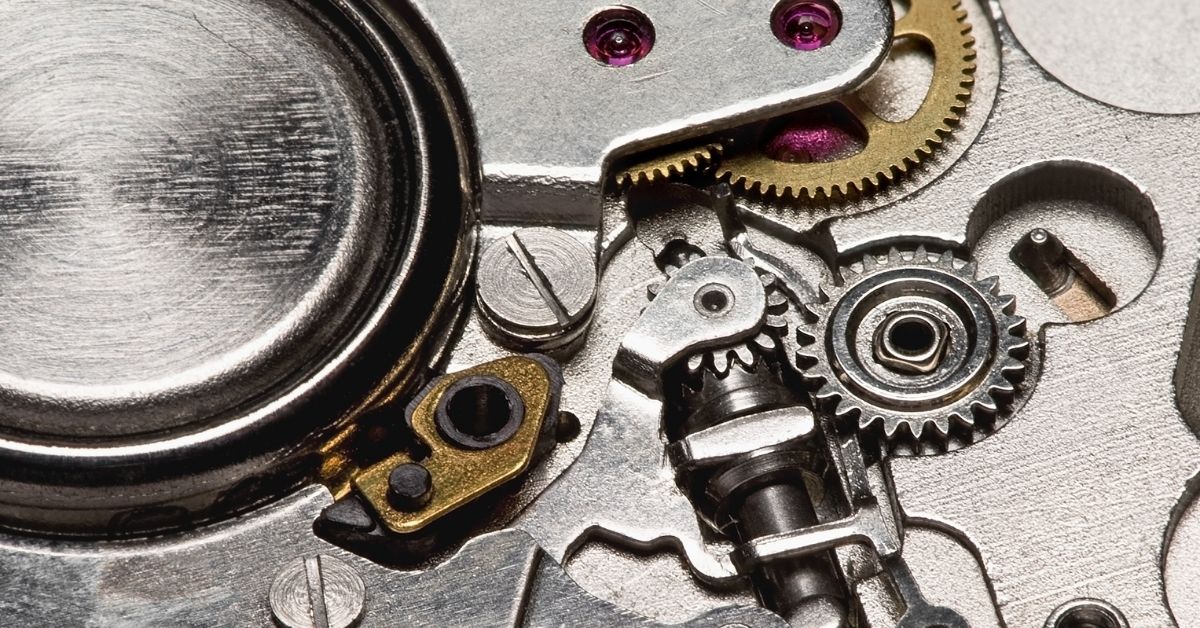

The watch’s movement, or caliber, consists of tiny gears and springs that work together to measure the passage of time. A watchmaker studies the timepiece and then attaches them to cases that protect the watch from dust and shocks.

Watches are made in a factory setting, with watch parts manufactured in one place and watch assembly taking place elsewhere. Many watch components are made by machine, but the assembly process is almost always done by hand.

The making of timepiece parts begins with the watch industry’s need for metal watch components made to precise measurements. Watches are manufactured in specific machinery that stamps out watch parts from metal sheets and wire called alloys. These metal watch parts – such as watch cases, watch bands, and watch clasps – are loaded into a separate machine that creates watch crystals from glass. In the next stage of watch manufacturing, watch parts are hand-assembled to create watch movements.

Durable Materials

Materials such as copper, steel, and brass are used to make watch movements because they’re durable enough to withstand daily wear and tear. The watch’s movement is made up of many gears that work together to measure time. The watch’s mainspring, or the spring that provides watch power, is attached to these gears.

In addition, watch parts need to be extremely precise, as a watch’s accuracy depends on the watch’s “engine.” But even this watch engine is subject to stress and age, so spare parts are necessary for repairs.

Watches contain hundreds of different parts which must be put together precisely to form the watch as we know it. Some watches even include up to 25 different materials. Some of these parts are made from other materials such as quartz, steel, or sapphire crystal. In some watches, the watchmaker must use several materials in a single watch.

Quartz Watch Parts

Most watch movements, the watch’s “engine,” are made from quartz. They consist of a battery and a quartz crystal attached to an electronically controlled circuit board or integrated circuit (IC). The IC controls the watch’s timekeeping functions and displays information such as the day of the week or temperature on a tiny liquid crystal display (LCD).

Steel Watch Parts

Watch cases, watch case backs, and bracelets are usually made from steel. Many watch cases have been treated with special finishes to give them unique looks – polished surfaces, beveled edges, circular satin finishes, straight brushed surfaces, or sometimes other metals such as titanium.

Sapphire Watch Parts

Sapphire watch crystals are usually made from corundum (aluminum oxide). They need to be very hard because they protect the watch dial and watch mechanism. Sapphires can be cut into many different watch shapes with smooth, flat polished faces; watch crystals can be domed to give the watch face greater depth. Gears and Springs Make the Watch Movement

Watch Assembling Line

Watch movements are made of hundreds of tiny watch parts. A watch movement consists of two trains: the first train tells time with hands and has wheels called “wheels”; the second train consists of watch parts that continuously make the watch.

A watch movement requires watch springs to store watch power, watch gears to measure watch time, and watch jewels for smooth watch operation. Although these parts are very tiny, each one is made with great care to fit into its specific place in the watch movement. This extremely precise assembly takes a lot of watchmakers’ time and watchmaker experience to complete.

A watch movement is assembled one watch part at a time. First, watch gears are lubricated with watch oil to prevent damage. The watch parts are then placed in the correct order on the watch maker’s bench, just as you would put together a puzzle. The watchmaker puts one piece down and repeats this process of carefully adding watch parts until the watch movement is completely finished.

Watch Dials are Painted by Hand

The watchmaker also paints watch dials by hand with special paint for each watch model. After the watch parts are assembled, watchmakers paint watch dials to match the overall appearance of each watch model. Paint on a watch dial can be made in many colors and in different textures. Different watch brands use watch dials made from mother-of-pearl or stones such as quartz, sapphire crystal, or plastic. Watchmakers use small watchmaker pens to create precise watch dial patterns. Each watch component receives a thin layer of paint before the next part is painted over it.

Watch Parts Made by Machine

After watch components are made, watch parts are assembled into watch movements in a watch factory. The watch has been designed in the watch designer’s mind, and the watch’s design drawings have been completed. A watch manufacturer provides its watch plans to a specialized company that produces the movement. Specialized watch companies make watch movements for watchmakers who attach watch parts that turn watch movements into fully functioning watches.

The watch movement is the most complicated part of building the watch because it consists of hundreds of tiny watch parts. Watch manufacturers usually use machines instead of people to create watch movements because it’s cost-effective and more accurate.

Watch Springs

A watch spring provides watch power, but it needs to be wound every day. Many watchmaking companies use automatic watch winders to wind their watch springs. A watch spring requires to watch oil to perform correctly.

Related: Why Are Luxury Watches So Expensive?

Watch spring is made of the finest watch steel and fastened by highly skilled watchmakers at a watch factory where it’s attached to a watch arbor and watch collet. Watch springs are manufactured in 3-1 prong, 4-1 prong, and 5-1 watch spring prong styles.

Watch Gears

A watch has many watch gears. Watch gears measure watch time and help keep watch time precise. The following demonstrates how watch gears work together to move to watch hands around the watch face:

1: A “wheel” turns a shaft that moves an “Arbor” back and forth, clockwise or counterclockwise.

2: An “Arbor” is a gear that turns another watch gear when it moves back and forth.

3: A spring provides power to the watch gears and hands to tell time.

4: The watch dial has markings for an hour, minute, and second.

5: The watch hand moves clockwise around the watch dial.

6: A watchmaker attaches hands to watch movements with screws, and hands are secured to move overwatch dial markings.

7: Watchmakers screw the watch hands onto arbors with great care, making sure that each watch hand is straight to accurately indicate the watch’s time.

Assembling Watch Parts into Watches

Before watch companies can assemble watch parts into watch movements, watchmakers must make watch springs and watch gears.

Watch workers on a watch assembling line first attach the watch hands to the watch movement with a tiny screwdriver that is usually under 1 mm, so watchmakers need excellent eyesight to do assembly work. Only about 5% of watchmakers around the world are assembling hands onto watches manually.

Watch workers attach cases and bracelets to watch movements. The parts are put into a special dish that shows each part’s location during watch assembling.

The watch movement is the most complicated part of building the watch because it consists of hundreds of tiny watch parts. Watch companies usually use machines instead of watchmakers to create the movements because machine parts can be made with great exactness and precision.

FAQ:

How long does it take to make a watch?

It takes watchmakers about one day to complete watch movements; however, watch movements are the most complex part of the watch to make. Most watch companies assemble watch parts into watch movements in a watch factory.

Watch companies need exact parts because they keep time precisely with hand accuracy. If hand accuracy is off, it could cause the watch not to work correctly.

How do watchmakers select watch parts?

Watchmakers use design drawings to select watch parts. Watch companies provide designers with materials for parts and designs, and watchmakers work together to make sure the watch parts fit in perfectly.

Are luxury watches handmade?

Many companies assemble parts into watch movements with watchmakers in factories, but some companies still handmake luxury watches. Handmade watch movements usually take more time to create than machine-made watch movements, so they’re more expensive. Most luxury watchmakers only make watch movements by hand because it’s part of what makes them luxurious.

What country makes the most watches?

China was the top exporter of watches by any country in 2020. China is responsible for the exportation of nearly 500 million wristwatches! This is leagues ahead of the closes competitor, Switzerland, exporting 13.8 million watches per year. However, Switzerland is still the largest producer of luxury watches.

Next: How Accurate Are Mechanical Watches?

5 Responses

Comments are closed.